Shear Properties of Polymers

The shear properties of polymers are important in many applications, particulalry when polymers are used for structural parts. The simplest case is a homogeneous isotropic body. For this case, the mechanical response depends on only two constants, the shear modulus G and the Poisson ratio ν.

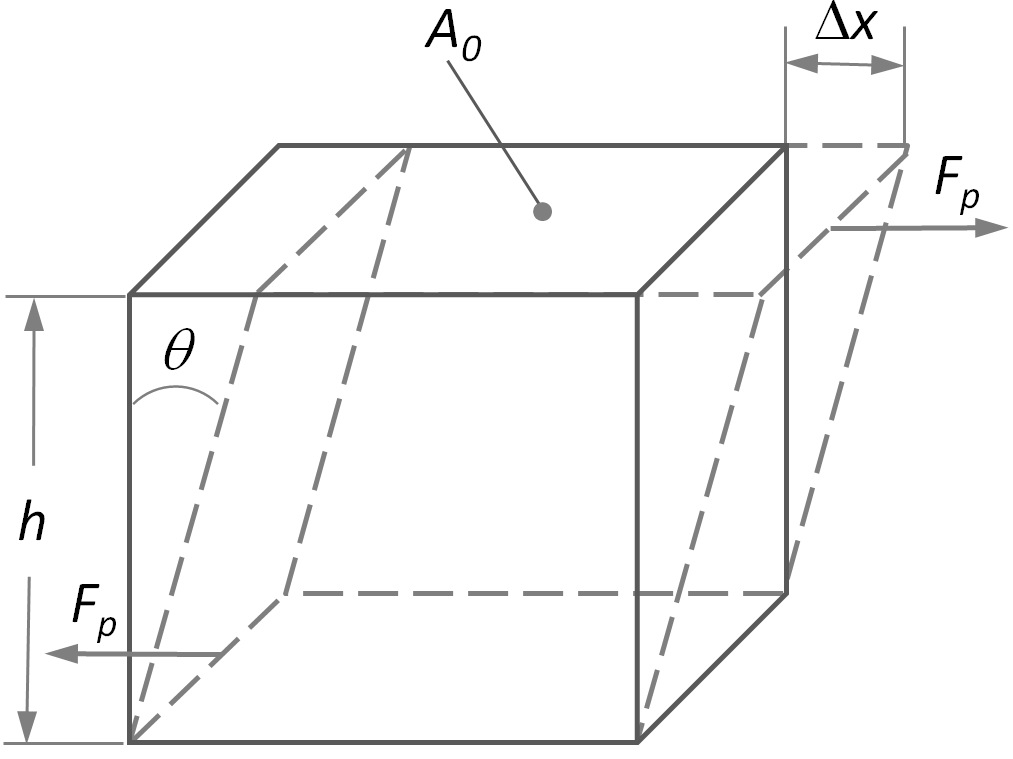

The figure below shows a simple shear deformation of a solid body. The body has the shape of a cube which has been deformed by a force F, acting in a plane A0 parallel to the deformation.

Shear Deformation of a Solid

For small strains, the deformation of the cube is elastic, that is, the deformation is homogenous and after removal of the deforming load the specimen returns to its original size and shape. Furthermore, the shear stress (τ) is directly proportional to the shear strain (γ), that is, the material obeys Hooke's law:

τ = G γ

where G is the shear modulus. It is the slope of the stress-strain curve, i.e., the ratio between an incremental increase in applied stress, Δτ, and an incremental deformation, Δγ. G is a measure for the stiffness of a material. The reciprocal of the shear modulus is the shear compliance, J, defined by

γ = J τ

In a stress-strain experiment, a sample is sheared at a constant shear rate and the stress, τ, is measured as function of strain, γ.1 In most cases, the stress-strain response of a shear sample is reported in terms of nominal or engineering stress and strain. The nominal or engineering shear stress is defined as the force divided by the initial (undeformed) area of the surface in which the shear force acts:

τe = F / A0

and the engineering shear strain is defined as the angle of deformantion, tan θ, which is equal to the amount of deformation, Δx, to the hight of the cube, h:

γe = tan θ = Δx / h

For isotropic materials and elastic deforamtion where Hooke's law is valid, the shear modulus and the tensile modulus can be related through the Poison's ratio ν:

E = 2 (1 + ν) G

Thus, only two of the three properties have to be measured.

References & Notes

The shear modulus G is often measured with a torsion pendulum tester or DMA by subjecting the specimen to an oscillatory deformation. The complex shear modulus G* is given by the expression

|G*| = (G'2 + G''2)1/2

The storage modulus G' in this equation represents the elastic behavior and is a function of shear and strain amplitude and phase angle.

M.D. Lechner, K. Gehrke, E.H. Nordmeier, Makromolekulare Chemie, 1993

L.H. Sperling, Introduction to Physical Polymer Science, New York 1992